A production line is an important thing in business; it’s often the core of a company’s operations, as their products roll straight off the end of the conveyor belt here, ready to hit the shelves and make a profit. Usually the production line runs perfectly smoothly, and you run into few issues that cut your company’s productivity in half.

However, this isn’t always the case, and problems should be accounted for in your production line plan. After all, many things could be slowing down or outright stopping your company’s entire production altogether, and you’ll need to keep an eye out for them.

So, because of this, we’ve listed the top three common issues with manufacturing, especially in a small business like yours.

Security Vulnerabilities

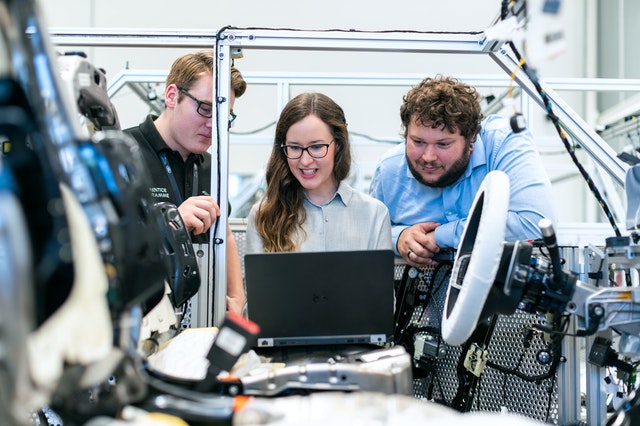

If you’re running a modern production line, you’re going to be using a lot of applications to keep it smooth, with little user input. This frees up the factory for other tasks, such as maintenance, and can make the operation much cheaper overall.

However, when it comes to keeping the production line safe, a computer program will never match a human’s input. After all, a computer program can have plenty of code vulnerabilities that can grind production to a halt, and any malicious outside attacks can find these in a matter of minutes.

Too Much Dirt

Maybe the products you’re producing aren’t being tested sufficiently? It’s happened multiple times in the past, with plenty of sectors having to recall products thanks to dangerous materials and/or dirt getting into the makeup. And because of this, quality assurance should be at the top of your list of priorities.

Indeed, using things like Mold Release Agents as a regular part of your production cycle is baseline standard. Similarly, having regular inspections of products, with a standardized checklist to follow, will ensure that anything that goes out to the shops is of saleable quality. This can save you a lot of money in the long run.

A Bad Product

Finally, even just a ‘bad’ product can do a lot of damage to your product line, mostly in terms of slowing it down and stopping you from focusing efforts elsewhere. Because even when a product sells well, it can be bad. It can be of low value, thanks to it being your only product, and there’s usually a distinct lack of innovation going on in your brainstorming sessions.

How do you deal with a bad product? Refine more products and bring them to the market. See how they sell, and determine what makes them better than the product you already have. Similarly, try not to be hesitant in taking a product out of production for a little while.

A production line is only as strong as the systems it relies on, and the products it produces. Make sure your technology has no exploitable vulnerabilities, and that your quality assurance checks are of high quality. And most of all, don’t be afraid to retire a bad product!

No comments yet.